Digitmakers.ca

Filaments Depot Red HTPLA

Filaments Depot Red HTPLA

Filaments Depot HT( High Temperature) premium PLA is high heat , high viscosity resin.

HTPLA is high grade premium high temperature PLA that withstand High Temperature and high viscosity resin

To achieve the crystalline state , HTPLA 3d printed part need to be heat treated in the oven (heat treatment must be done after 3D printing process)

Filaments Depot team have followed the following process to heat treat the following parts as shown in the photo below.

1- Place the 3d printed part with HTPLA in Conductive oven on a piece of wood or aluminum foil .

2- Heat the oven 90°C to 110°C--preferred temperature stable oven.

3- Keep the part 30 to 60 min depends on the part volume and wall thickness.

The following test conducted on 3d printed samples The one on the right was heat treated following the above steps and the sample on the left was not heat treated .

Deflection of the non heat treated part started in 5 minutes , Oven was heated to 120°C , and samples placed as shown the deflection of non-heat treated part start in 5 min while the heat treated part maintain its shape even after 30 min under 120c .

With every spool, you will receive a large resealable bag with a slider as well as an extra desiccant pack. Your filament spool is kept safe when not in use with the bag and additional desiccant. You'll always find your filament freshly dried and free of dust or dirt particles when you use it.

- Made with recyclable spool and box

- Includes an extra resealable bag in the box

Print settings

- Printing Temperature : 205°C - 235°C

- Heated Bed: 60-65°C Bed Temperature

-

Filament Diameter: 1.75±0.03mm

- First layer usually 5°C-10°C higher than subsequent layers.

- Sticks well to Glass with PVA Glue ,BuildTak, PEI, or blue tape.

- Cooling Fan: Highly recommended.

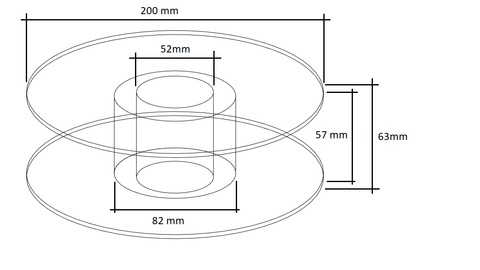

- Empty Spool Weight : 140 Grams

- Gross Weight :1140-1170 Grams

- Net Weight : 1KG

NOTE :

Great results can be achieved with printing speed 20-40mm/s for infill specially with Bowden setup 3d printers using 0.4 mm nozzle size.

For All metal hot-end , try to print with high flow rate and/or higher temperature , while 3d printers with Teflon-lined hot-ends you can can print at regular flow rate and lower temperature.

Mechanical Properties

- Tensile modulus ISO 527-1 3500 MPa

- Tensile strength ISO 527-1 50 MPa

- Elongation at break ISO 527-1 ≤ 5%

- Charpy notched impact, 23°C ISO 179-1eA ≤ 5 kJ/m2

- Heat deflection temp, amorphous2 ISO 75-1 60°C ( Non-Heat Treated part)

Share

Subscribe to our emails

Be the first to know about new collections and exclusive offers.